Design & Fabrication

When designing or fabricating steel, there are often certain requirements one must consider. Hot-dip galvanized steel has its own set of design and fabrication considerations one should be familiar with before the start of the project. Incorporating the design and fabrication recommendations will help ensure the best quality coating and most successful project. The design and fabrication considerations for hot-dip galvanizing differ from other coatings, but are simple to follow once you become familiar with them.

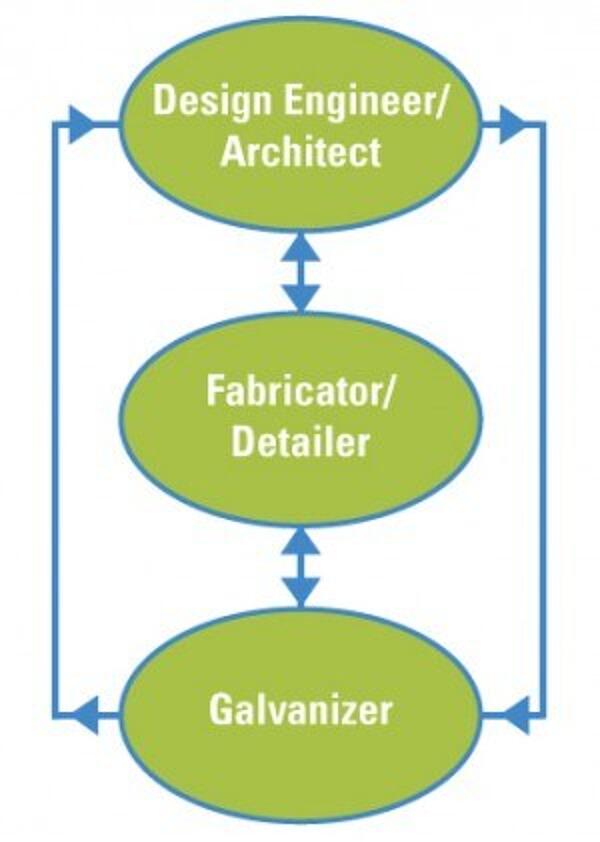

Whether designing a galvanized project for the first time, or the 100th time, the key component to a successful project is communication between the architect, engineer, fabricator and galvanizer. Opening the lines of communication early in the design and fabrication process can eliminate potential costly pitfalls later in the process. A few discussion topics good to cover while the project is being designed include:

- Steel Chemistry & Surface Condition

- Size & Shape

- Process Temperature/Heat

- Venting & Drainage

- Welding

- Threaded Parts/Connections

- Post Galvanizing Design/Use

Understanding these aspects of the galvanizing process and how they can affect the coating and finished product's outcome will help ensure everyone's expectations are met and may optimize turnaround time, and minimize cost to ensure top-quality hot-dip galvanized steel.